-

anilox rollerslaser cleaningequipment

anilox rollerslaser cleaningequipment

anilox rollers laser cleaning

why inelme?

Because its more than 20 years of experience in the sector and presence in over 40 countries around the world means Inelme is able to offer flexography professionals the technology and the solutions their printing units need to reach optimal performance levels.

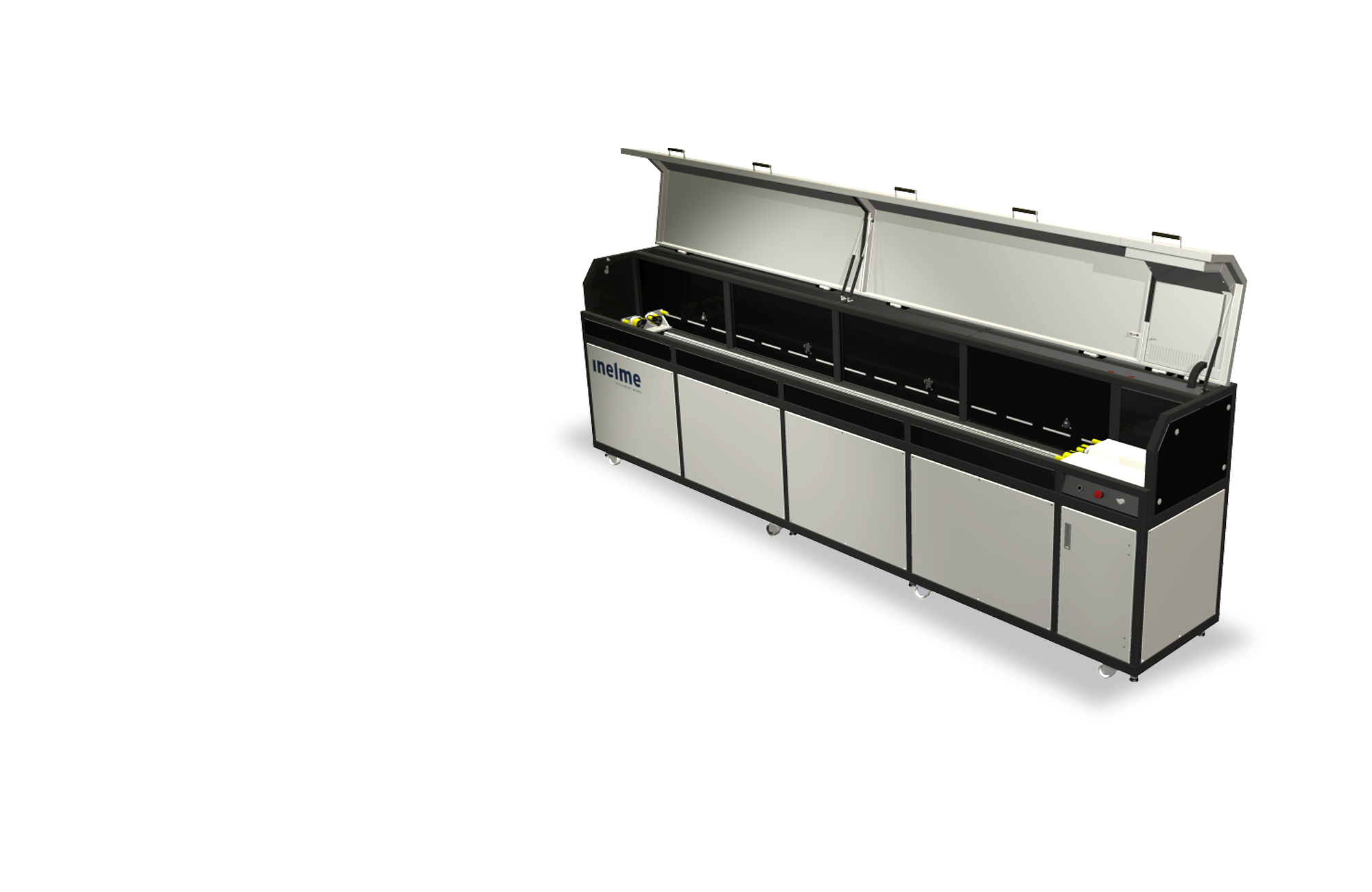

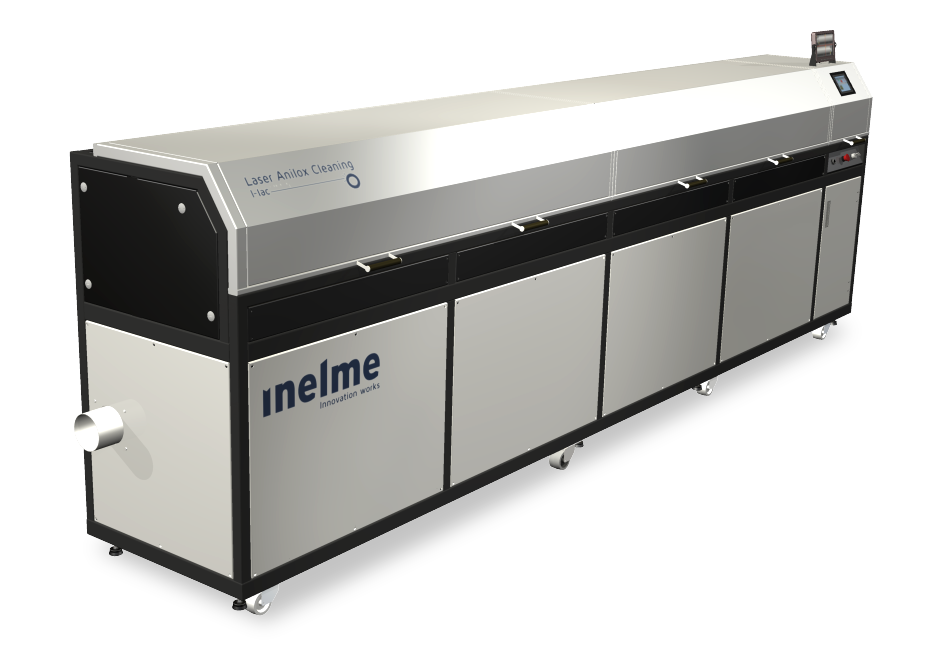

Cleaning the anilox rollers of flexographic printers has always been one of the biggest problems for industry professionals. If the rollers are not perfectly clean, their transfer capacity is reduced. Thanks to laser technology, the Inelme cleaning system is very efficient, and this translates into correct and stable colour intensity with optimisation of results and work times.

Flexxo Printing Solution

Inelme’s Italian partner, can help you in the choice of washing solutions that are suitable for optimising your work output and respecting an environmental context that is now subject not only to the rules of common sense, but also to increasingly stringent international regulations.

Plus

|

The first to develop the laser washing system for anilox |

|

The fastest laser washing system |

|

Zero maintenance costs |

silent, inexpensive and ecological

cleaning of anilox rollers

To guarantee long-lasting high-quality printing, it is important to keep anilox rollers scrupulously clean all the time, removing residual ink before it solidifies and blocks the cells. If the rollers are kept clean, the transfer of the volumes of ink remains uniform and this benefits the print quality.

To wash anilox rollers rapidly, safely and inexpensively, Flexxo Printing Solution has chosen Inelme washing systems, suitable for cleaning rollers and sleeves up to 3 metres in width. The process is fast, simple and completely automatic, leaving the anilox 99% clean without the use of chemical products, bicarbonates, etc., and it produces no waste to be disposed of.

In addition to saving on detergents and gaining time to keep machines up and running, users save on maintenance: Inelme machines work at full capacity for up to 100,000 hours.

the Company

printing unit

ancillary devices

Via Cairoli 4, 28100 Novara (Italia)

P.Iva: 02344210030 +39 338 6661927

m.gionta@flexxops.com

Design: Elena Crespi - Web Programming: Immagina Creative Communications.

Chiudendo il banner e proseguendo la navigazione si acconsente all'utilizzo.

OK

Disclaimer