-

cliché washerand film cleanermachines

cliché washerand film cleanermachines

plate and film cleaning

why polymount?

Flexxo Printing Solution

the exclusive source in Italy for Polymount cleaning products, helps its customers to understand and appreciate the advantages of the best maintenance solutions for keeping efficiency levels high.

Plus

|

Innovative technology for process optimization in support of printing |

|

Considerable savings in consumable materials |

|

Environmental concern by supporting the converter |

high-level innovative solutions

for plate and film cleaning

Polymount is an expert at researching and proposing truly innovative solutions in printing plate and film cleaning systems.

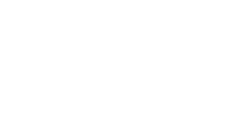

The Polymount cliché washer system is the only one in existence that works in 2 directions in both the cleaning phase and the drying phase. Thanks to the Polymount cliché washer, printing plates are thoroughly cleaned completely automatically. Just press a button and the machine performs the cleaning process perfectly in about 5-10 minutes per square metre.

Polymount produces the best horizontal cliché washer system sold in the world as well as cleaning fluids and detergents developed in-house, which guarantee the best results and the greatest durability of polymer photo plates.

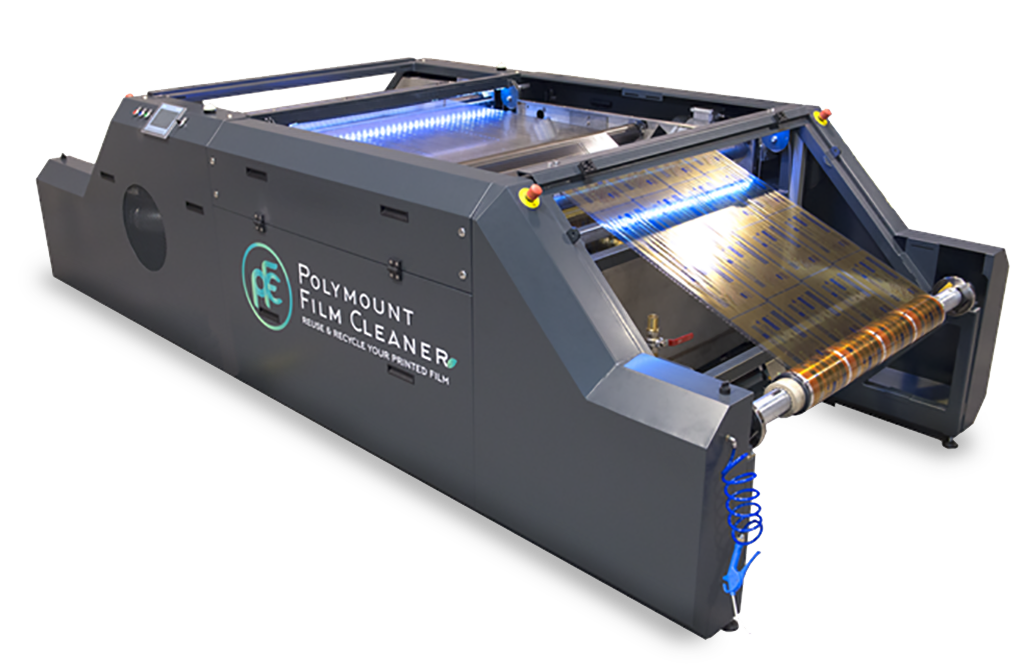

Polymount Film Cleaner is the first machine that removes ink from printed film, allowing film to be reused for print runs over and over again. Polymount Film Cleaner can clean up to 80 metres of printed film per minute, it works with water-based and solvent-based inks, and it cleans all the substrates of the film.

The machine works in an extremely simple way: Polymount Film Cleaner unwinds the reels and passes the film through detergent tanks where specific detergent liquids remove all the ink from the film. Patented technology is then used to dry the film before it is perfectly rewound. At the end of the cycle, the reel appears as new, does not need to be disposed of and may be reused immediately.

the Company

printing unit

ancillary devices

Via Cairoli 4, 28100 Novara (Italia)

P.Iva: 02344210030 +39 338 6661927

m.gionta@flexxops.com

Design: Elena Crespi - Web Programming: Immagina Creative Communications.

Chiudendo il banner e proseguendo la navigazione si acconsente all'utilizzo.

OK

Disclaimer