-

clichésleevesand carriers

clichésleevesand carriers

sleeves and carriers

why pam?

Flexxo Printing Solution

advises Pam to ensure the customer’s best performance and print quality.

Plus

|

Long-standing technical expertise (since 1982) in the production of rollers used for flexographic and converting printing |

|

The first developer of anilox sleeve in 1996 |

|

The lightest sleeves currently present on the market |

Long-standing technical expertise

and the best print quality

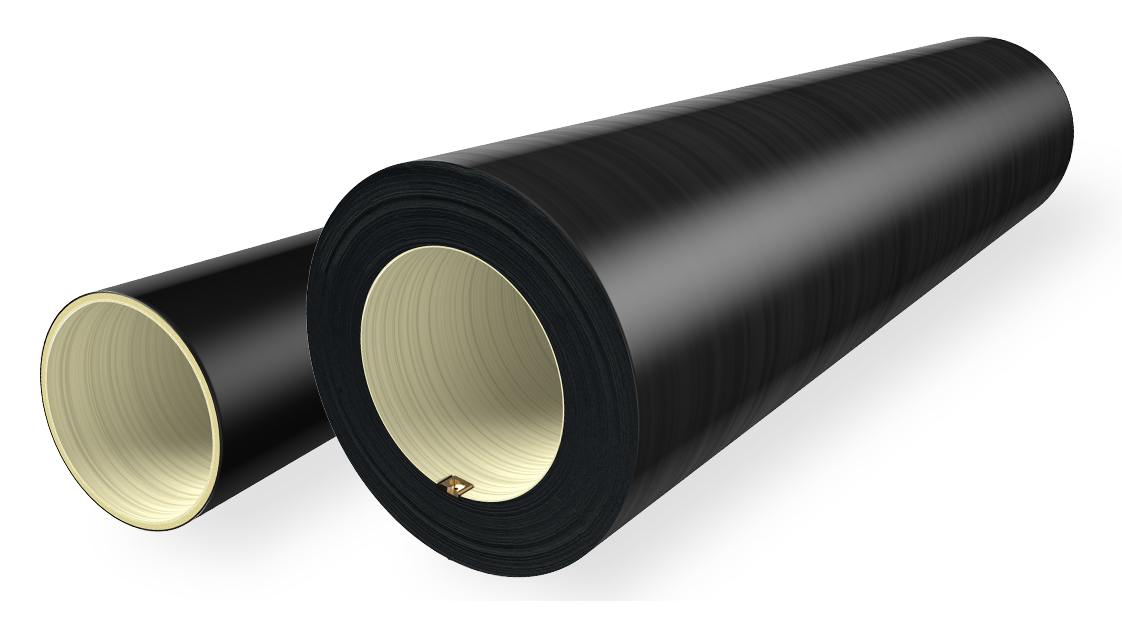

Cliché Sleeves

These are sleeves for the printing plate assembly with cushioning double-sided tape, which have been specifically designed for the flexible packaging industry. Later they are assembled on the mandrel by compressed air. Besides the classic thin sleeve made by glass fiber which is light, hard and resistant to solvents, we have come up with a sleeve characterized by a multilayered polyurethane lining. It guarantees dimensional stability and also a great precision and solvents resistance during the printing process. Both versions can be integrated with notch. These sleeves can be antistatic or conductive. Additionally, Pam has developed a special sleeve designed for assembly on hydraulic-expanding mandrels.

Possible dimensions: from Ø47,862 mm to Ø1012,088 mm, maximum length 5000mm

Materials: Fiberglass / Fiberglass + polyurethane

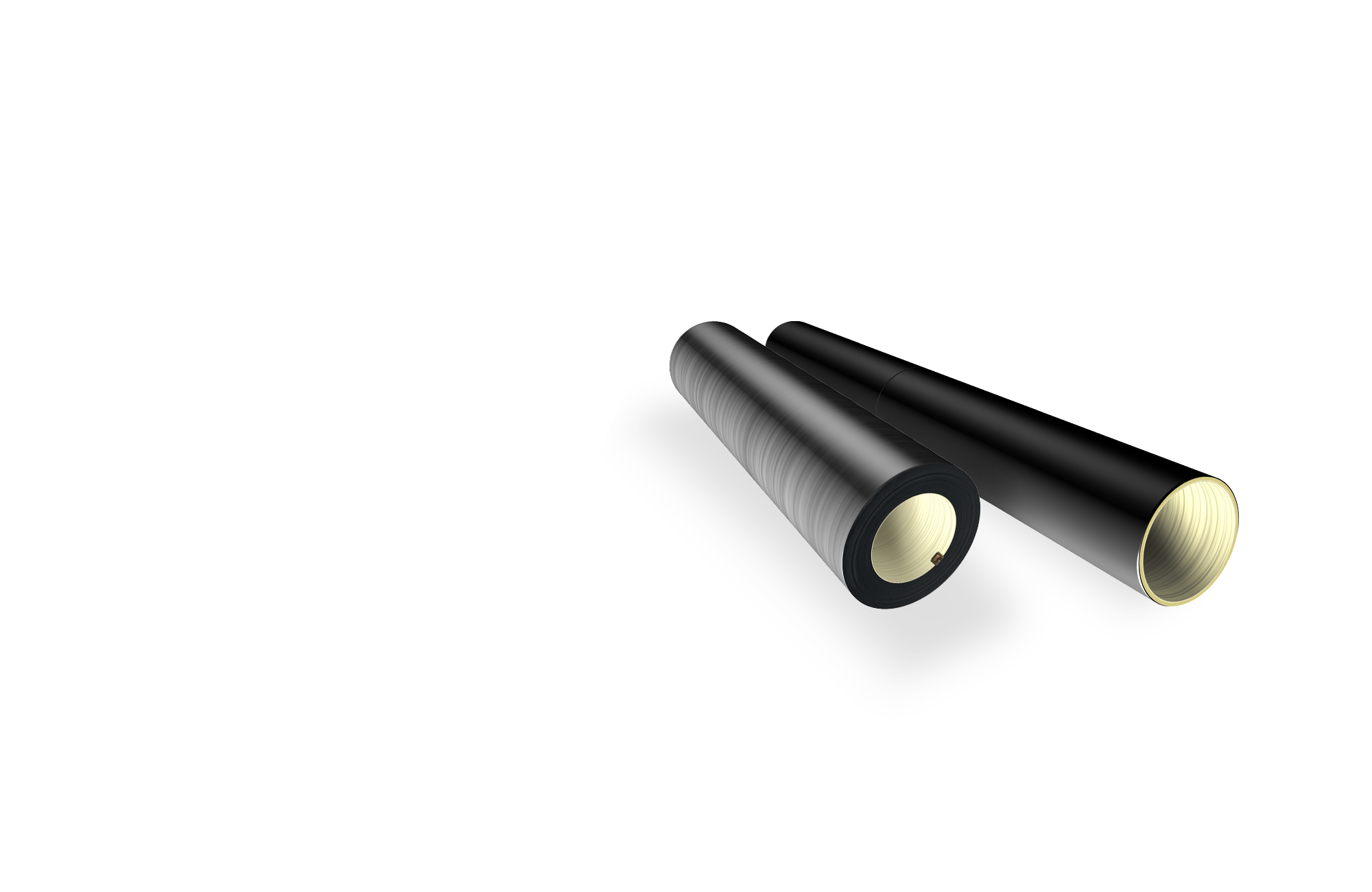

Carriers

Carriers are supports made in order to reduce the difference between the outer diameter of the air spindle and the inner diameter of the sleeve. Essentially, a carrier increases the outer mandrel size without the need of a too tick sleeve, reducing its weight and consequently the cost. The use of high-module carbon fiber allows a greater structural stiffness, which results in reduced vibrations and a consequent better print quality.

Possible dimensions: from Ø47,862 mm to Ø1012,088 mm, maximum length 5000mm

Materials: Fiberglass + Aluminum + Carbon / Fiberglass + Polyurethane + Carbon

the Company

printing unit

ancillary devices

Via Cairoli 4, 28100 Novara (Italia)

P.Iva: 02344210030 +39 338 6661927

m.gionta@flexxops.com

Design: Elena Crespi - Web Programming: Immagina Creative Communications.

Chiudendo il banner e proseguendo la navigazione si acconsente all'utilizzo.

OK

Disclaimer